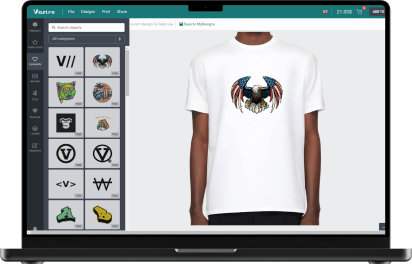

We are better able to realize direct garment printing

Highlight Features

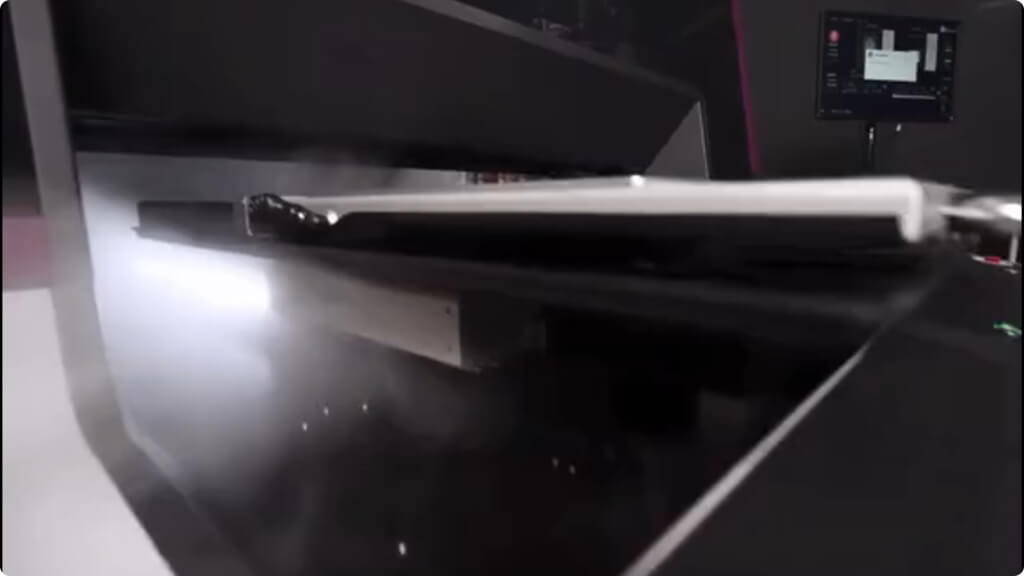

Advantages in print quality

1、High Resolution Output

- With advanced inkjet technology and a resolution of up to 1200 dpi or even higher, Conray printers are capable of delicately reproducing complex patterns and gradient color effects.

2、Excellent color representation

- Multi-color printing systems (e.g., CMYK, LC, LM, etc.) for wider color gamut coverage and vibrant, lifelike colors.

- Natural color transition, not easy to appear color difference problems.

3、Consistent print quality

- Equipped with precision printhead auto-cleaning and calibration functions to ensure consistent print quality without broken lines or uneven ink jet.

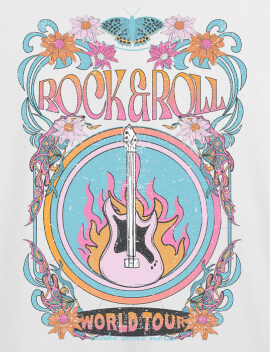

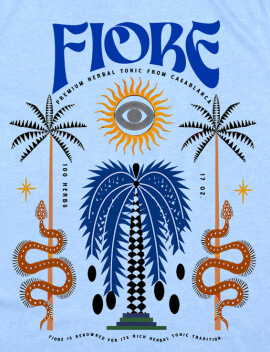

How is Apollo better than a screen printing

The use of digital printing technology enables the printing of higher resolution images with richer, fuller colors and clearer details. Higher accuracy can be achieved especially when working with complex and delicate designs.

Screen printing is not as fine as Apollo for complex patterns and gradient colors. The resolution and color reproduction of screen printing is relatively low, and color differences may occur.

friendliness

Adopting low VOC or no VOC environmentally friendly ink reduces pollution to the environment; the ink has strong adhesion, is not easy to fade, and has wide adaptability to a variety of materials, reducing the dependence on chemical substances.

The inks used in conventional screen printing often contain high levels of harmful chemicals, especially volatile organic compounds (VOCs), which are not only harmful to the environment, but can also affect human health.

flexibility

The digital process allows Apollo to respond quickly to small orders, especially for personalized and customized needs. There is no need to create screens or special molds, and the equipment starts up quickly, saving preparation time.

Traditional screen printing requires pre-made screens, which is not only time-consuming but also generates more waste for short runs or customized orders. Each time a color or design is changed, the screen needs to be re-prepared, resulting in less production flexibility.

consumption

Thanks to the digital technology, the waste in the production process is greatly reduced. There is no need to duplicate templates or stencils, reducing material waste. Each production step is precisely controlled, avoiding inventory problems caused by overproduction.

Screens and printing templates need to be produced, which can generate large amounts of waste, especially during color changes. In addition, the use of ink in the screen printing process is wasteful and often requires cleaning of the equipment, which leads to more water and energy consumption.

Advantages in productivity

1、High-speed printing

- The print area per hour has been dramatically increased to meet the demands of high-volume production without sacrificing quality.

- Different patterns can be quickly switched on demand to shorten production lead time.

2、Suitable for small batch customization

- Supports per-piece printing, eliminating the need for plate making and saving time and cost for small orders.

- More flexibility to meet individual order requirements, from samples to large shipments.

3、Supports a wide range of fabrics

- Can adapt to cotton, polyester, silk, linen, nylon and other fabric materials.

- Particularly suitable for diversified customization needs, such as sportswear, dresses, home decorations and so on.

The beauty is in the details

There is almost no exhaust gas or waste water emission during the printing process, which is more suitable for the modern green production concept.

Delivery details

We have three delivery speeds so that your shirts are delivered exactly when you need them: Standard 2-week delivery, our 1-week Rush option, or our delivered-in-2 days service, Lightning.

Standard

Loading...

Rush

Loading...

Lightning

Loading...

Short Sleeve T-shirts

Short Sleeve T-shirts

Cotton combed tight knit siro short sleeved shirt

Cotton combed tight knit siro short sleeved shirt

Batik T-Shirt

Batik T-Shirt

Vintage Wash T-Shirt

Vintage Wash T-Shirt

Long Sleeve T-shirts

Long Sleeve T-shirts

Crewneck Sweatshirt

Crewneck Sweatshirt

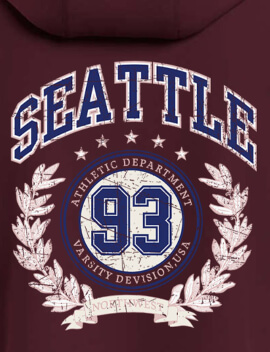

Hoodie

Hoodie

Necklaces

Necklaces

Bracelets

Bracelets

Rings

Rings

Earrings

Earrings

Jewelry Storage

Jewelry Storage

Floor

Floor

Rugs

Rugs

Floor

Floor